The turbocharger is broken, should I repair it? Which models are suitable?

The turbocharger is broken, should I repair it? Which models are suitable?

1: Does the turbocharger have repair value?

The supercharger is a high-value accessory, and a small piece of metal products will start at 1,000. Engineering machinery, marine engines, and superchargers for large generator sets cost tens of thousands of dollars. But not all turbochargers are suitable for repair. For example, the turbochargers on passenger cars and commercial vehicles, many people choose to buy cheap auxiliary parts after they break down. It is true that the price of auxiliary parts is cheap, but there is a big gap between the use of materials, processing technology, and design and manufacturing of auxiliary parts, which makes the auxiliary parts more prone to damage under the already harsh working conditions. This kind of sub-factory is cheap and even has four to five hundred yuan. This kind of turbocharger has no repair value, because if the damage is serious, the maintenance cost may be about the same as the price of buying a new sub-factory.

2: Which models are applicable for turbocharger repair?

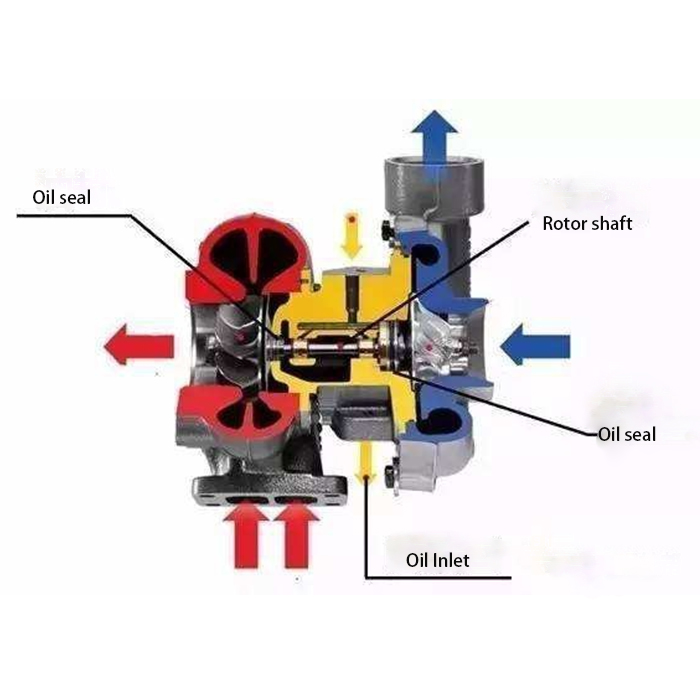

The original parts of the turbocharger are worth repairing if they are not severely damaged. There are other construction machinery, large generator sets, marine engines, etc., which are of higher value, and the residual value after damage is also large, so they have a greater maintenance value. Some friends may ask, what level can be achieved after repair? In fact, our intensive repair is not only as simple as replacing damaged parts, but also through various air pressure and airflow tests to confirm that the repair is complete. Make sure to use the data consistent with the original factory.

Of course, correct maintenance is the most important thing after the turbocharger is repaired.

1: Use good engine oil. Inferior engine oil will cause the floating main rotating shaft of the turbine to fail to lubricate and dissipate heat. Inferior engine oil will cause crystallization and wear to the turbocharger. Therefore, use engine oil that is resistant to high temperature and oxidation.

2: The air filter element is cleaned and replaced. Dust particles entering the turbocharger will cause the dust to collide with the high-speed turbocharger blades, resulting in unstable turbine operation and wear of the shaft sleeve and seals. Therefore, it is necessary to replace the air filter element.