Why does your turbocharger always leak oil? And no one else? What is it for?

Why does your turbocharger always leak oil? And no one else? What is it for?

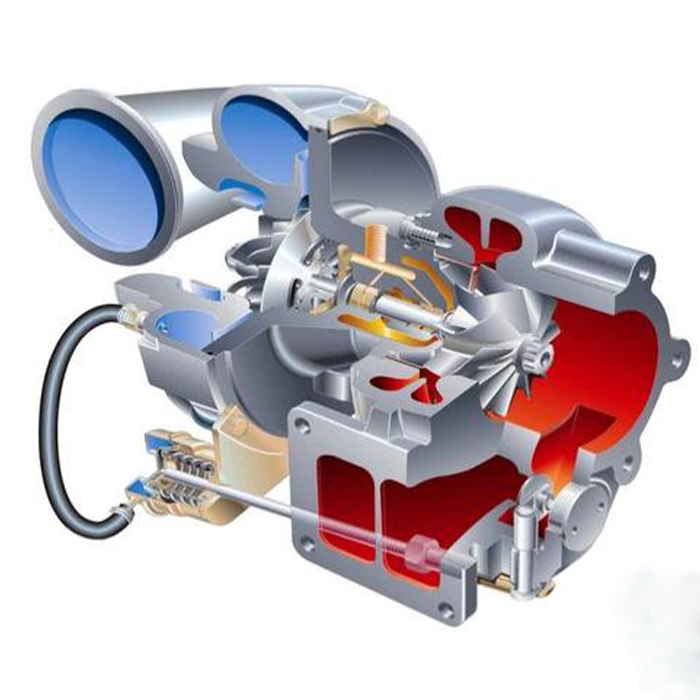

Oil leakage at both ends or one end of the turbocharger is one of the most common faults in use. Theoretically speaking, the oil that enters the intermediate under normal pressure, after passing through the bearing working surface, the oil pressure has become zero, but naturally flows downwards back to the engine's oil pan by gravity. Moreover, under normal working conditions, there is a certain gas pressure at the backs of the impellers at both ends of the turbocharger, so the oil will not flow from the low pressure area to the high pressure area. The main function of the sealing ring is to seal the gas in the compressor and turbine shell from leaking to the intermediate oil cavity. Only under special circumstances can it play the role of sealing the oil. Nevertheless, if used improperly, oil leakage at both ends of the turbocharger can still occur under the following conditions.

1 Long-term idling operation of the engine

When the engine is idling for a long time, a certain negative pressure will be generated at the back of the turbocharger turbine and the impeller, which will cause the oil in the intermediate to leak out. This is the result of special tests conducted by experts on the test bench many times. As a result, it is therefore necessary to avoid idling the engine for a long time.

2 Poor oil return

In use, if the oil return pipeline is deformed or blocked, the oil return is not smooth, the oil pressure in the intermediate is too high, and the compressor oil flows along the axial ends of the rotor and extrudes the sealing ring, causing oil leakage. Therefore, always check whether the oil return pipeline is unblocked to ensure that the oil can flow back to the oil pan normally.

3 Engine crankcase pressure is too high

If the exhaust pressure of crankcase exceeds the specified value, the pressure in the return oil pipeline of turbocharger will increase, and the return oil will not flow freely, resulting in oil leakage of seal ring. Always check the ventilation status of the crankcase and whether the lower exhaust pipe is clear. Setra engines should pay extra attention to the proper operation of the oil and gas separator to prevent the mixture in the crankcase from being pumped down the exhaust pipe into the compressor and cylinder, resulting in engine oil burning.

4 Air filter is blocked

After the engine is used for a long time, the air filter element will be blocked due to excessive dust accumulation, which will cause the negative pressure of the compressor intake to be too high, and the seal ring will leak oil due to the high negative pressure at the back of the impeller. Therefore, it is necessary to check and maintain the air filter regularly to ensure that the filter element is not blocked or punctured, and the normal air supply state is maintained.

5 The sealing ring is worn or failed

If the engine oil is not replaced for a long time, too much impurities in the engine oil will act as abrasives, causing the seal ring to aggravate and become thinner, and gradually lose its air-sealing and oil-sealing functions, resulting in oil leakage. The so-called impurities refer to foreign particles larger than 0.02 mm in the engine oil. These impurity particles can randomly flow into the oil film of the bearing and shaft and the seal ring, severely grind the rotating parts, and aggravate the wear and failure of the parts.

If your engine is not working properly, you may assume that it is a failure of the turbocharger, but in many cases, it is often directly related to the engine.