Five factors: Why are full turbochargers becoming more and more important?

Five factors: Why are full turbochargers becoming more and more important?

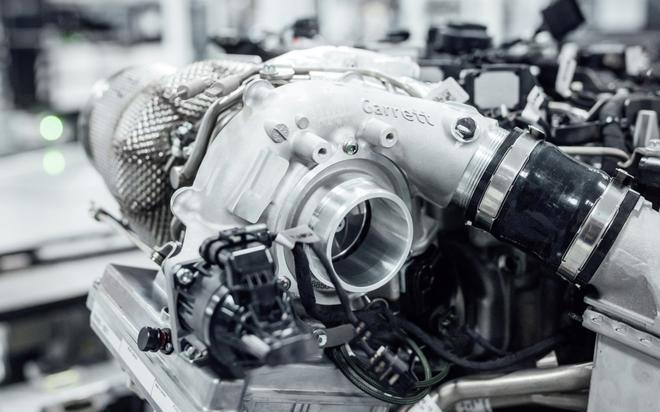

The power of a car engine depends on the number and size of piston cylinders? This has become history. ——Since the Swiss inventor made the full turbocharger in 1925, the performance of the engine has been greatly improved. What are the characteristics of this component, and why it is becoming more and more important-five interesting factors about full turbochargers:

1. The basic principle remains the same

The invention has a history of about 100 years, but its basic principles have not changed. The exhaust gas flow drives the turbine wheel to rotate, and the turbine wheel is connected to another impeller through a shaft. This impeller compresses the inhaled fresh air and presses it into the combustion chamber. A simple calculation can be made at this time: the more air that enters the combustion chamber in this way, the more oxygen molecules bind to the hydrocarbon molecules of the fuel during the combustion process-and this provides more energy.

2. Almost 300,000 revolutions

Finally, the full turbocharger can generate the highest possible air pressure to achieve the best results. In modern engines, the maximum speed of the compressor rotor can even reach 290,000 revolutions per minute. In addition, components can also generate extremely high temperatures. In general: Four different substances are gathered in the very small space of this component: high-temperature exhaust gas, cold charge air, cooling water and oil (the oil temperature must not be too high).

3. "Electrochemical advantage"

Under this prerequisite, the production of full turbochargers has become one of the most challenging tasks in the automotive manufacturing industry. This is not only for complex housings, but also for turbine shafts. They are made of high-performance materials and can withstand temperatures up to 1000 degrees Celsius without any problems. In this case, the use of electrochemical processes can bring great advantages. For example, when using this process, only one repetitive step is required to complete the dynamic balance of the turbine shaft. And it will not cause thermal damage to the material, even the hardest material, the tool wear caused by it is also very small-compared with the traditional cutting process, these are great advantages.

4. Increasingly important

The production of full turbochargers is becoming more and more demanding, which is related to the general trend of automobile energy saving and emission reduction: the displacement of many internal combustion engines is decreasing, but the compression of the machine can make the performance consistent or even improve. Interestingly, due to the increase in the weight of the machine and the supercharger cooler, the weight of the emission reduction engine even exceeds that of similar engines without emission reduction design. Therefore, R&D personnel began to reduce the shell wall thickness to reduce weight, which in turn further increased its processing requirements.

5. Future challenges

Turbocharging is still the key technology for the development of energy-saving and efficient engines. However, various technological trends also bring new challenges. This exhaust gas recirculation (EGR) system is one of the most important measures used to reduce diesel engine emissions. Therefore, the full turbocharger must press more air into the combustion chamber to provide it with enough oxygen.