High temperatures are the big killer of turbochargers

High temperatures are the big killer of turbochargers.

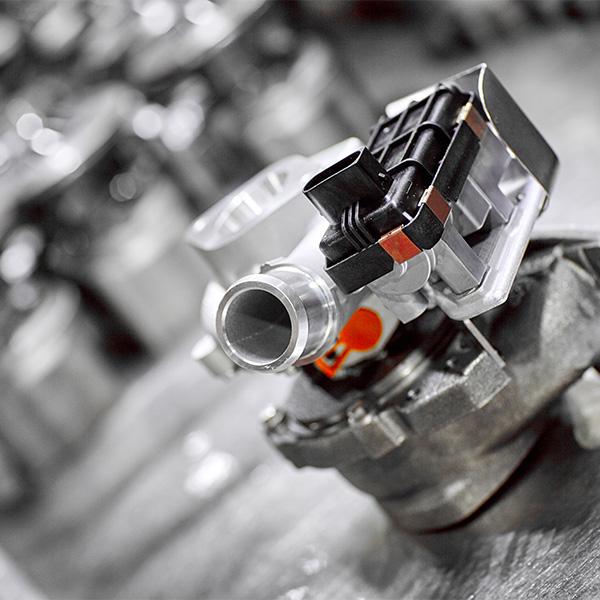

The turbocharger has a simple structure, does not consume the power of the engine itself, and has a high boost value. These factors lead to a strong advantage of turbocharging. However, the principle of turbocharging makes it have the biggest hidden danger: high temperature. It is this hidden danger that has led to the delay in turbocharging entering the civilian field.

There are several sources of heat. The first is the exhaust gas temperature. As we mentioned earlier, the exhaust gas temperature of a gasoline engine can reach 750-900 degrees at full load, and it is also nearly 700 degrees under normal working conditions. These exhaust gases will cool down in the process of pushing the turbine to rotate. Where does this temperature go? It is absorbed by the turbine blades.

Secondly, the rotating shaft connecting the turbine and the impeller rotates at a high speed of more than 100,000 revolutions, and the friction between the rotating shaft and the bearing will generate a lot of heat. After Z, the intake impeller continuously sucks in air, compresses the air, and its own temperature will also increase. These factors add up to put the entire turbo in absolute "hot".

The turbine failure caused by high temperature is mainly due to the deformation and ablation of the turbine blade and the failure of the rotating shaft. Engineers have come up with a variety of ways to deal with this problem over the years, but there are basically two: use more heat-resistant materials and use more efficient cooling methods.