Turbochargers have four main advantages

Turbochargers have four main advantages

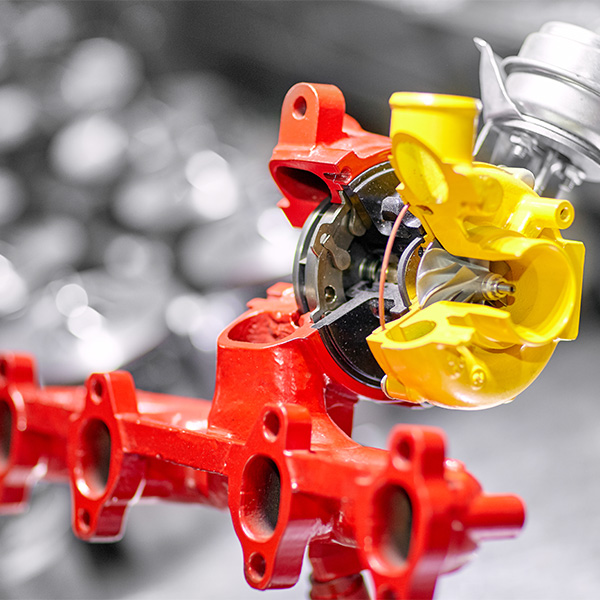

1. Increase the engine power. When the engine displacement is unchanged, the density of the intake air can be increased to allow the engine to inject more fuel, thereby increasing the power of the engine. The power and torque of the engine after adding a supercharger should increase by 20% to 30%. On the contrary, under the requirement of the same power output, the cylinder diameter of the engine can be reduced, and the volume and weight of the engine can be reduced.

2. Improve engine emissions. Turbocharger engines reduce the discharge of harmful components such as particulate matter and nitrogen oxides in the engine exhaust by improving the combustion efficiency of the engine. It is an indispensable configuration for diesel engines to meet emission standards above Euro II.

The earliest patent application for a turbocharger was in 1905, when Dr. Alfred Buchi of Sulzer Brothers Research and Development applied for a patent for the first turbocharger, a power-driven axial supercharger, but given the industrial Level, Dr. Buchi did not make the first efficient turbocharger product. In 1911, the Winterthur supercharger factory in Switzerland started, and in 1915, a prototype aircraft engine supercharger was manufactured, which was driven by engine exhaust gas, and the main purpose was to overcome the negative impact of high-altitude thin air on power. During World War II, superchargers made by General Electric (GE) lifted the aircraft to an altitude of 10,000 meters.

After forced turbocharging, the temperature and pressure of gasoline engine compression and combustion will increase, and the tendency of knocking will increase. In addition, the exhaust temperature of gasoline engines is higher than that of diesel engines, and it is not suitable to increase the valve overlap angle (the time when the intake and exhaust valves are opened at the same time) to strengthen the cooling of the exhaust gas, and reducing the compression ratio will cause insufficient combustion. In addition, the speed of the gasoline engine is higher than that of the diesel engine, and the air flow changes greatly, which is easy to cause the response lag of the turbocharger. In response to a series of problems arising from the use of turbochargers in gasoline engines, engineers have made targeted improvements one by one, so that gasoline engines can also use exhaust gas turbochargers.

After the engine runs at high speed for a long time, it cannot be turned off immediately. When the engine is working, a part of the oil is supplied to the turbocharger rotor bearing for lubrication and cooling. After the running engine is suddenly stopped, the oil pressure drops to zero rapidly, the high temperature of the turbo part of the supercharger is transmitted to the middle, the heat in the bearing support shell cannot be quickly taken away, and at the same time, the turbocharger rotor is still rotating at a high speed under the action of inertia. Therefore, if the engine is suddenly stopped in the hot state, it will cause the oil retained in the turbocharger to overheat and damage the bearings and shafts. In particular, it is necessary to prevent the engine from suddenly turning off after a few kicks of the accelerator.