What’s the exhaust bypass valve on the turbocharger compressor? What happens if it breaks?

What’s the exhaust bypass valve on the turbocharger compressor? What happens if it breaks?

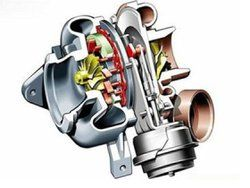

On the turbocharger compressor of a car engine, there is a small cylinder, one end of which is connected to the compressor of the supercharger through a pipe, and the other end is a tie rod, which is connected to a small valve on the turbine. Many people don't know what it is for. The following article explains its function for everyone.

Generally speaking, the more exhaust gas and the higher the exhaust gas pressure, the faster the turbine rotates, the stronger the supercharging effect of the engine, and the more violent the engine work; the more violent the engine works, the more exhaust gas will be produced. The greater the pressure is, this will form a "dead loop", if this continues, it will cause the engine speed to become higher and higher (speed phenomenon), and eventually become uncontrollable and cause damage to the engine. This phenomenon is called "overcharging" of the engine.

In order to avoid “Over-pressurization”, the exhaust bypass device is designed on the turbocharger compressor. It is composed of a control chamber, a pull rod, an exhaust bypass valve, etc. , the control chamber is the core component. It is a pneumatic cylinder composed of diaphragm and spring. One end is connected to the compressor of the supercharger. The pressure above the diaphragm is equal to the pressure in the compressor, the other end is connected with the waste gas bypass valve.

When the pressurization pressure in the compressor exceeds a predetermined value, the air pressure pushes the diaphragm compression spring, causing the pull rod to push outward, opening the exhaust bypass valve, and guiding part of the exhaust gas away from the turbine, instead, a bypass valve installed in front of the turbine goes directly into the exhaust pipe, which reduces the amount and pressure of exhaust gas that drives the turbine, which in turn slows the turbine and reduces the pressurization pressure, avoid the engine as a result of “Over-pressurization”and lead to the phenomenon of flying. When the compressor pressure drops to a certain value, the pressure above the diaphragm is not enough to overcome the spring force, the spring will spring back, driving the connecting rod to move to close the by-pass valve, and the exhaust gas will all drive the turbine to run, the turbocharger compressor pressure is increased again until the next bypass valve is opened.

However, the failure rate is very low, and failures are generally caused by man-made damage. It must be known :that the setting and verification of the spring preload pressure in the bypass valve control air chamber are carried out on special equipment, and the user cannot adjust or change at will. If we are carrying the machine, it is convenient to directly hold this lever by hand, which will cause the lever to bend and deform, which will affect the opening timing of the bypass valve. If the connection between the tie rod and the bypass valve falls off, then the bypass valve loses control and remains in the open state, and the engine will suffer from insufficient boost pressure, resulting in insufficient power and power drop. In addition, if the air pipe of the control air chamber breaks or leaks, the bypass valve cannot be opened, and the engine will be overcharged.

With the increase of engine speed, the force of compressing intake air is getting greater and greater, and may even exceed the design limit. At this time, it is necessary to release a part of the exhaust gas to prevent them from entering the turbocharger compressor to participate in work. The role of the bypass valve is That's it.