What are the commonly used turbocharger accessories and the development history of accessories?

What are the commonly used turbocharger accessories and the development history of accessories?

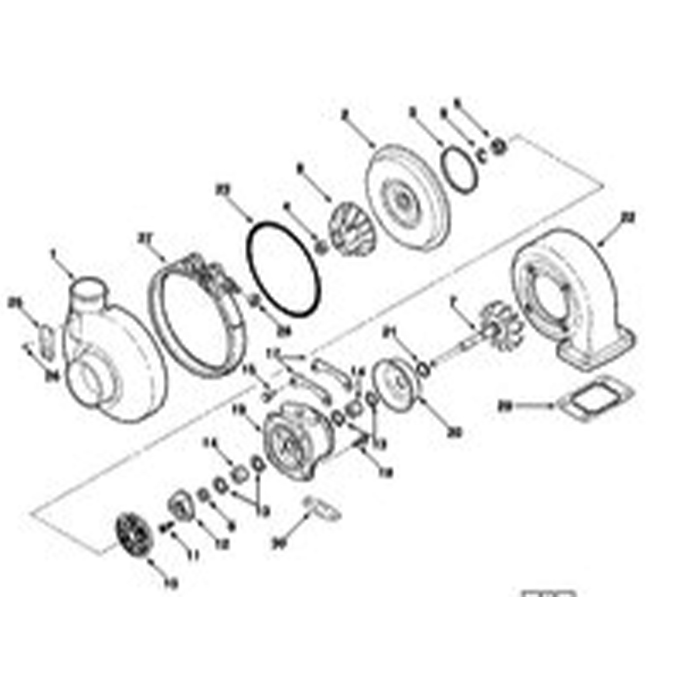

1. Impeller: The core components of automotive turbocharger accessories can be divided into casting impellers and fully processed impellers according to different production processes.

2. Intermediates: core components of automotive turbocharger parts.

3. Precision bearing parts: The processed materials include aluminum, copper (lead-containing and lead-free), alloy steel, stainless steel and nickel-based alloys and other special materials.

4. Gear shaft: The transmission gear shaft of the variable-section turbocharger is one of the core components of the variable-section turbocharger. The variable-section turbocharger relies on the gear on the precision gear shaft to drive the shaft to transmit torque. Give the fork, adjust the size of the nozzle ring section through the fork, so as to control the size of the intake air volume, so that the impeller can have pressure to rotate in a timely manner at various speeds of the engine, so that the turbocharger can quickly intervene and improve the engine. Use power and efficiency.

5. Compressor casing: The compressor casing is mainly used for the casing of the turbocharger, which is made of aluminum alloy through casting, precision machining and other processes. Automatic upgrading of production units and production lines is achieved through core making, pouring, cleaning, machining, testing and other equipment.

Whoever invented the turbocharger is more widely known to be Swiss engineer Bi ch, who patented it in 1905. It is mainly used in aircraft engines and tank engines. It wasn't until 1961 that General Motors in the United States tentatively included turbochargers in a certain type of vehicle it produced. In the 1970s, it became the turning point for the turbocharger and introduced the Porsche 911 with a supercharged engine. However, the non-Swedish SAAB Saab company, which rejuvenated turbo technology, introduced the SAAB99 model in 1977 and promoted turbocharging more widely, but at the time turbochargers were limited to gasoline installed in cars. above the engine. It wasn't until the mid-1980s that truck manufacturers in Europe and the United States applied turbocharging technology to their respective diesel engines, and during these 10 years, domestic vehicles gradually became popular with turbochargers.

What we usually call a turbocharger is actually an air compressor that compresses air to increase the intake air volume of the engine. Typically, a turbocharger uses the inertial force of the exhaust from the engine to propel the turbine within the turbine chamber. The turbo, in turn, drives the turbocharger fitting coaxial impeller, which pumps the air sent by the air filter duct to pressurize it into the cylinder. When the engine speed increases, the exhaust emission speed and the turbo speed also increase in tandem. The impeller compresses more air into the cylinder. The increased pressure and air density burns more fuel, increasing the amount of fuel and tuning the engine accordingly. As the speed increases, the output of the engine can be increased.