The manifestations and symptoms of a broken turbocharger, as well as common failures and treatment methods.

The manifestations and symptoms of a broken turbocharger, as well as common failures and treatment methods.

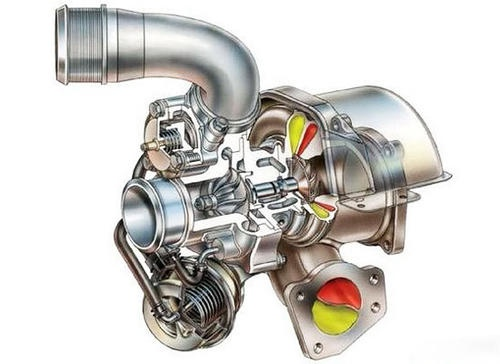

The turbocharger uses the exhaust gas discharged from the exhaust pipe to drive the turbine to rotate at a high speed. At the same time, the compressor impeller is driven to rotate at a high speed through the rotor shaft. Its speed can reach 50000~230,000r/min. Pressure, the density of the air entering the cylinder is greatly increased, and the power of the diesel engine is improved. Turbocharger is an important part used to increase engine power and reduce exhaust emissions. Due to improper use, maintenance and maintenance, it is easy to malfunction and cause the engine to fail to work normally.

The performance of a broken turbocharger

1. The engine is weak

2. The exhaust emits black smoke

3. Increase in fuel consumption

4. There is a sharp, harsh sound when running the engine

5. Engine oil enters the intake pipe

1. The turbocharger leaks oil

Phenomenon 1: The oil consumption is large, but the exhaust smoke is normal and the power is not reduced.

Reason: This situation is generally caused by oil leakage.

Approach:

(1) First, check whether the external oil pipes of the engine lubrication system (including the inlet and return pipes of the turbocharger) are leaking;

(2) Check whether the exhaust outlet of the turbocharger is organic oil. If there is organic oil, it can be judged that the seal ring at one end of the turbine is damaged, and the seal ring should be replaced.

Phenomenon 2: High oil consumption, blue smoke from the exhaust, but the power does not drop.

Reason: Due to the oil leakage at the compressor end of the turbocharger, the engine oil enters the combustion chamber through the engine intake pipe and is burned. There are several possibilities:

(1) The oil return pipe of the turbocharger is not unblocked, and the oil accumulates too much in the middle support of the rotor assembly, and flows into the compressor impeller along the rotor shaft.

(2) When the seal ring or oil slinger near the end of the compressor impeller is damaged, the oil enters the impeller chamber from this, and then enters the combustion chamber through the inlet tube along with the pressurized indoor air.

Approach:

(1) Open the air outlet of the compressor or the straight pipe (rubber hose) of the engine's air intake, and check whether the oil is adhered to the nozzle and the pipe wall. If yes, please check if the return pipe of the turbocharger is unblocked. If it is not smooth, it is caused by excessive oil accumulation at the intermediate support. The oil return pipe should be dredged and reinstalled.

(2) If it is unblocked, it is caused by damage to the sealing ring or oil sling ring at one end of the impeller, and the supercharger should be disassembled for repair.