How to deal with a Full turbocharger damage?

How to deal with a Full turbocharger damage?

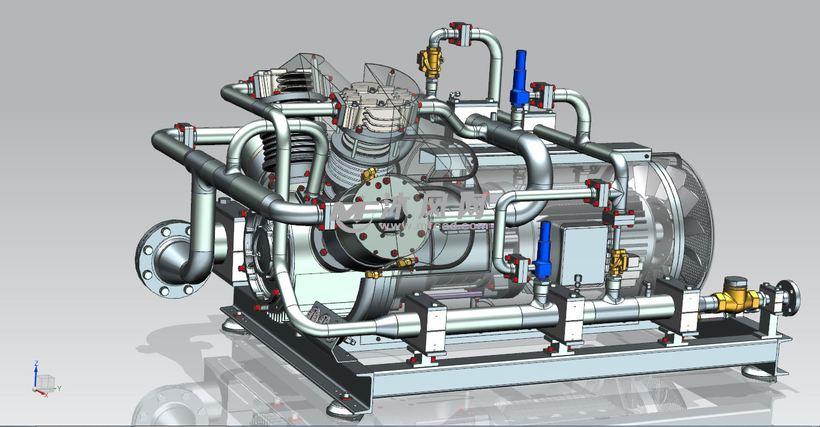

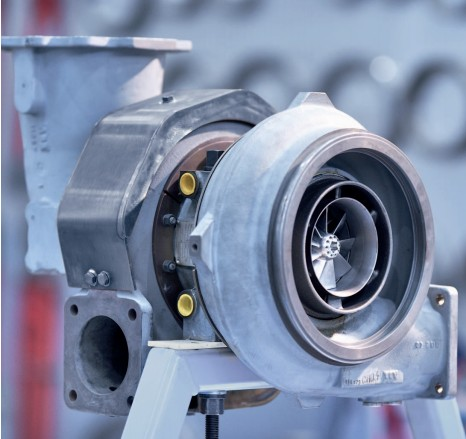

Full Turbocharger is an important part used to increase engine power and reduce exhaust emissions. Due to improper use, maintenance and maintenance, it is easy to malfunction and cause the engine to fail to work normally. Some common faults and solutions are introduced as follows:

<Oil spill

Phenomenon 1: The oil consumption is large, but the exhaust smoke is normal and the power is not reduced.

Reason: This situation is generally caused by oil leakage.

Approach:

1. First, check whether the external oil pipes (including the oil inlet and return pipes) of the engine lubrication system are leaking;

2. Check the exhaust gas outlet for organic oil. If there is organic oil, it can be judged that the seal ring at one end of the turbine is damaged, and the seal ring should be replaced.

Phenomenon 2: High oil consumption, blue smoke or black smoke from exhaust, and power drop.

Reason:

1. The gap between the piston and the cylinder is worn too much, and the oil rushes into the combustion chamber and is burned.

2. In the process of air being sucked in by the full turbocharger, the air flow encounters greater resistance. (Such as the air filter is blocked, the air intake hose is deformed or flattened by suction, etc.), the pressure at the air inlet of the compressor is low, causing oil to leak into the compressor and enter the combustion chamber along with the compressed air to be burned.

Approach:

1. Check whether there is inorganic oil in the wall of the air inlet straight hose, whether it is squashed, so that the air flow is blocked or the air filter element is blocked.

2. If the nozzle and wall of the pipe have organic oil, the air filter element should be cleaned or replaced.

<The full turbocharger has a metal friction sound

Phenomenon: The exhaust emits black smoke, the power drops, and the machine makes abnormal noises.

Reason:

1. If there is metal friction sound, it is caused by excessive wear of the rotor bearing or thrust bearing, and the friction between the impeller and the full turbocharger shell.

2. If it is not the sound of metal friction, but the sound of airflow, it is the rotating sound generated by the high-speed rotation of the rotor, or the air leakage caused by the poor connection at the inlet and exhaust ports.

Approach:

1. The former should be repaired by replacing damaged spare parts according to wear and tear.

2. The latter should be carefully distinguished and targeted solutions.

Therefore, when the full turbocharger has oil leakage or frictional noise during use, it can be repaired according to the above-mentioned content.